Defect Detection on Production Lines

Revolutionary AI-powered quality control that surpasses traditional inspection methods. Achieve unprecedented accuracy, reduce waste, and enhance operational efficiency.

Revolutionary AI-powered quality control that surpasses traditional inspection methods. Achieve unprecedented accuracy, reduce waste, and enhance operational efficiency.

In today's fast-paced manufacturing environment, ensuring product quality is paramount. Defects, even minor ones, can lead to significant financial losses, reputational damage, and customer dissatisfaction. Traditional manual inspection methods are often slow, prone to human error, and struggle to keep up with the demands of modern production lines. This is where advanced defect detection systems, particularly those powered by Artificial Intelligence (AI), come into play. These systems offer unparalleled precision, speed, and consistency, revolutionizing how manufacturers identify and address imperfections.

At DigitFactory, we understand the critical need for robust quality control. Our AI Vision solution is specifically designed to address these challenges, providing automated inspection capabilities that surpass conventional methods. By leveraging cutting-edge AI and machine learning technologies, we empower manufacturers to achieve higher quality standards, reduce waste, and enhance overall operational efficiency.

Defect detection in manufacturing has undergone a significant transformation. What was once a rule-based, often rigid process, has evolved into a dynamic, data-driven approach. Legacy visual inspection systems, while foundational, were not built to handle the complexities of today's diverse product lines and intricate designs. They often suffered from high false positive rates, requiring engineers to spend valuable time reviewing non-defects, and their rigidity meant constant reprogramming for every new product iteration. More critically, they were often blind to subtle defects like micro-cracks or early-stage anomalies that could lead to failures down the line.

AI is rapidly replacing these legacy systems due to its ability to learn from actual data rather than hardcoded patterns. AI-powered systems continuously improve with operator feedback, seamlessly integrate with existing camera systems, and can drastically cut false positives while operating at line speed, even on complex inspections. This shift represents a quality control revolution, enabling manufacturers to achieve unprecedented levels of accuracy and efficiency.

AI visual inspection is not a one-size-fits-all solution; different inspection contexts demand distinct AI architectures. Choosing the right approach depends on various factors, including production needs, part complexity, defect variability, and performance expectations. There are three primary AI approaches to defect detection:

This approach excels in environments where rapid decisions are paramount, and the inspection requirement is binary—a simple Go/No-Go determination. Classification works by assigning each image a label or set of labels, without the need to spatially localize the defect. It's highly efficient and scalable, making it ideal for mass production environments with limited variation in part geometry.

For instance, in pharmaceutical production, it can be used for tablet or capsule sorting, or in packaging lines for presence/absence checks. Its capabilities include multi-label detection for issues like bent, scratched, or missing components, and threshold-based pass/fail filtering. This method is most effective when speed is critical and granular location or precise measurements of defects are not required.

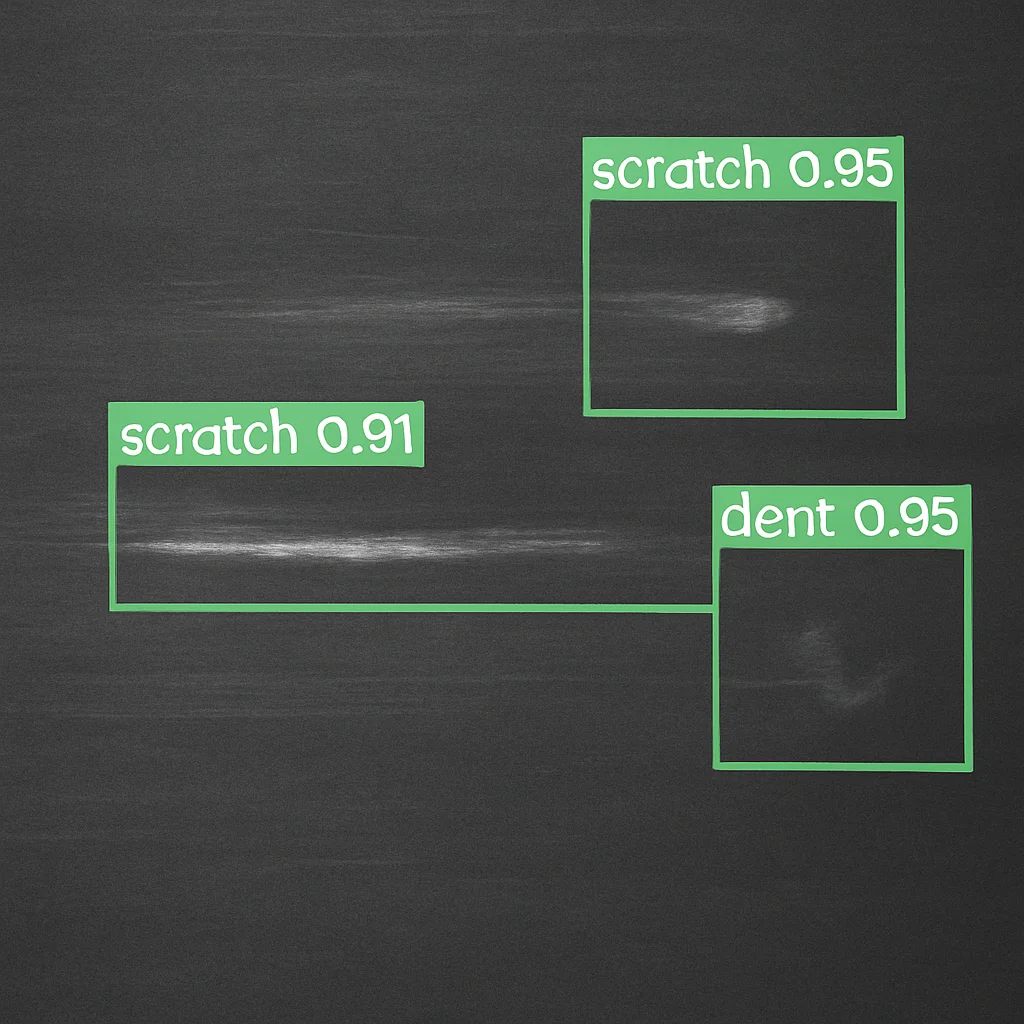

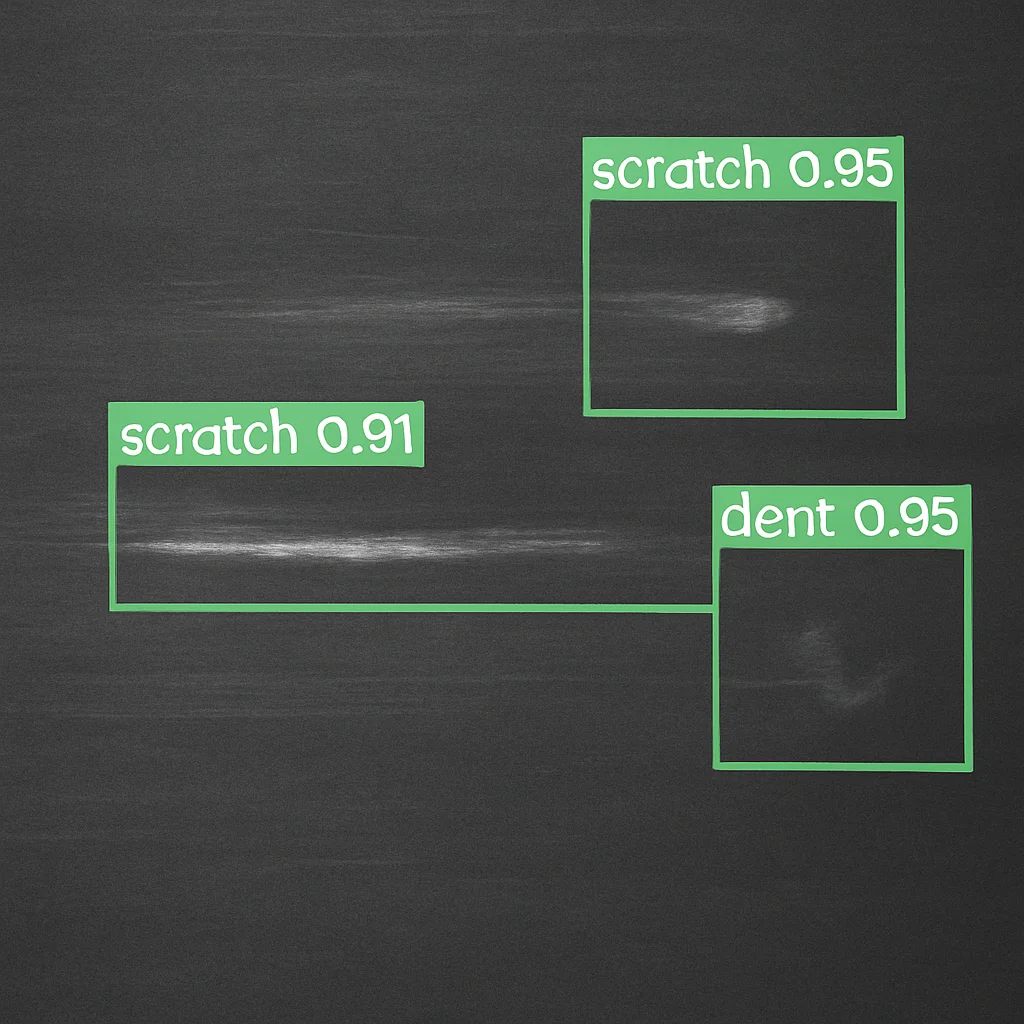

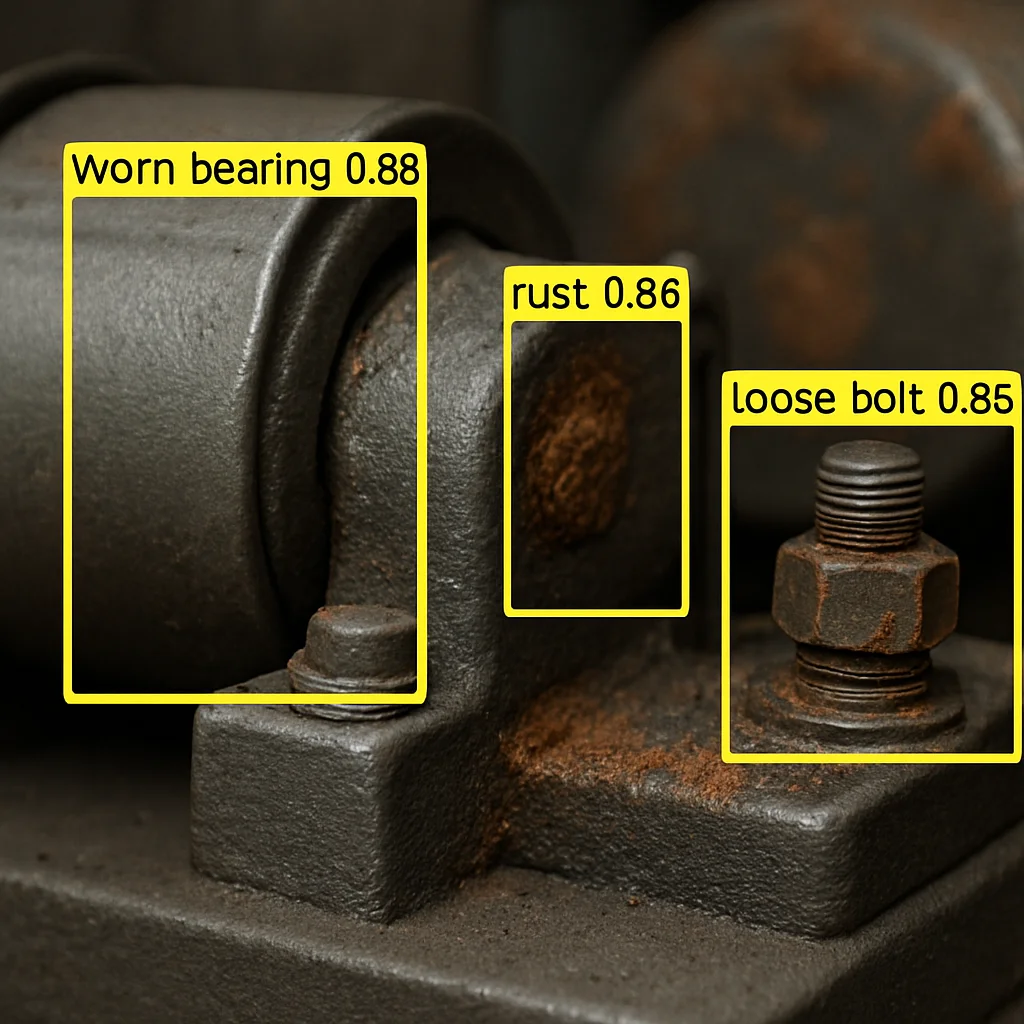

Object detection offers a more granular level of analysis by identifying both the class and the precise location of defects using bounding boxes. This method provides a good balance of accuracy and contextual detail, making it well-suited for situations where knowing what is wrong and where it occurred is crucial, but pixel-perfect outlines are not necessary.

In practice, object detection is invaluable when inspection results must inform immediate repair actions. Common applications include solder joint bridging detection in PCB assembly, weld seam inspection in automotive manufacturing, and connector misalignment in electronics. Its capabilities extend to identifying what and where a defect is, thereby enabling more effective downstream repair decisions. This approach is preferred when defects need to be targeted and fixed, not merely flagged, and when balancing inspection speed with resolution is key.

Segmentation is the most precise of the AI approaches, assigning each pixel in an image to a class—either defect or non-defect. This method enables the measurement of a defect's area, volume, and surface coverage, providing pixel-perfect analysis. While compute-intensive, segmentation is often employed in slower inspection stages where measurement accuracy directly impacts yield or regulatory compliance.

The output from segmentation can be used to generate real-time masks, quality scores, or even predictive indicators of upstream process issues. Typical applications include paint finish quality control, surface uniformity checks in pharmaceutical products, and overlay inspection on semiconductor wafers. This approach is essential when defect geometry matters significantly, such as for measuring crack length or spot size, and for inline metrology requiring precise scoring.

At DigitFactory, our AI Vision solution embodies the cutting-edge of defect detection technology. Leveraging industrial cameras and NVIDIA Jetson for edge processing, our system provides real-time defect detection with significantly higher precision than traditional manual inspection. With capabilities to detect defects as small as 0.25 mm at speeds up to 60 frames per second, AI Vision ensures that even the most subtle imperfections are identified.

Our solution seamlessly integrates with existing PLC (Programmable Logic Controller) systems, allowing for immediate OK/NOK (OK/Not OK) signals, automated rejection control, and comprehensive archiving. This full traceability includes NOK image archives, detailed quality reports, and audit data, providing a complete historical record for every product. The benefits are tangible and immediate:

Real-time AI analysis identifying potential issues before they become defects

Scrap Reduction

Product Traceability

Return on Investment

Real-time Processing

Our AI Vision solution is versatile and can be applied across various manufacturing sectors, addressing specific quality control challenges:

With over 10 years of experience in industrial automation, DigitFactory possesses a deep understanding of real production environments, including challenges like dust, vibration, and variable lighting. Our commitment to Edge AI processing means that critical decisions are made locally, ensuring speed and reliability. We speak the language of manufacturing, providing solutions that are not only technologically advanced but also practical and seamlessly integrated into your existing operations.

Our collaboration model is designed for your success: we start with a fast pilot project, offer a success-fee model where you pay only for achieved results, and guarantee success with transparent metrics and measurable outcomes. We also provide comprehensive support, including training, service, and continuous system development.

Ready to transform your production line with intelligent defect detection? Contact DigitFactory today to learn how our AI Vision solution can help you achieve superior quality control, reduce costs, and enhance your manufacturing efficiency.

Let's build the future of smart manufacturing together